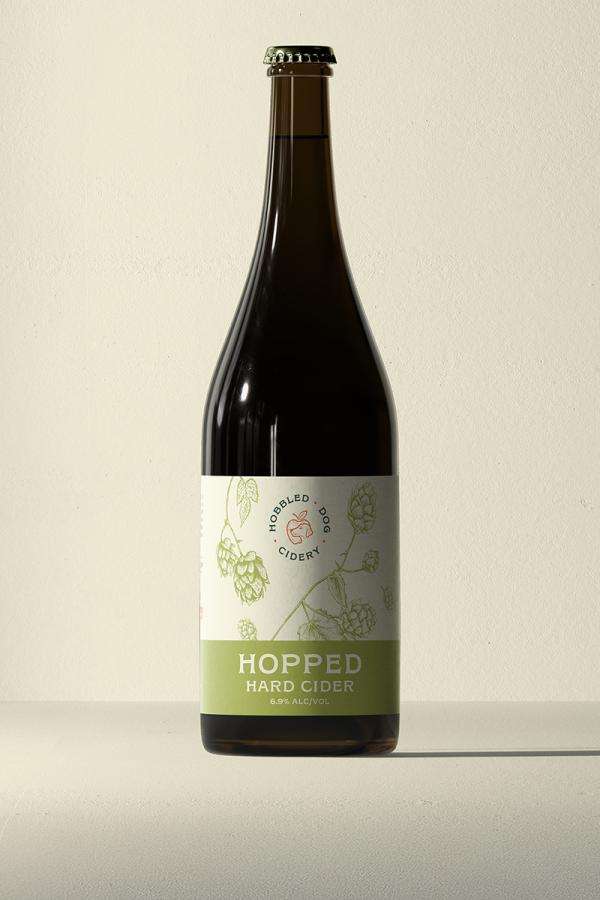

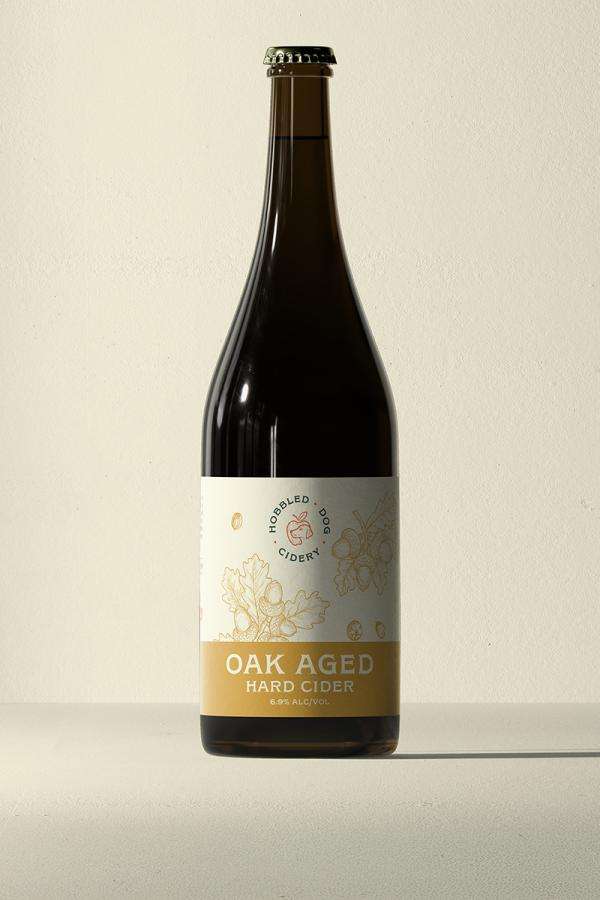

Our Ciders

Great cider begins in the orchard. With adventurous tasters and apple enthusiasts in mind, we craft unique and classic ciders from more than a dozen apple varieties, some of which are grown at our farm in Paradise, Utah. At our cidery in Logan, Utah, we press apples, ferment juice, and age each batch to perfection. Some ciders are available year-round; others are seasonal or limited releases.